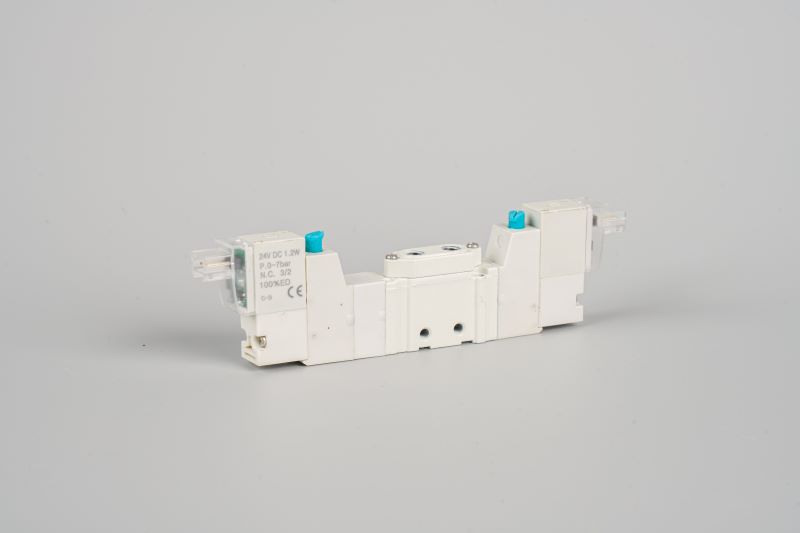

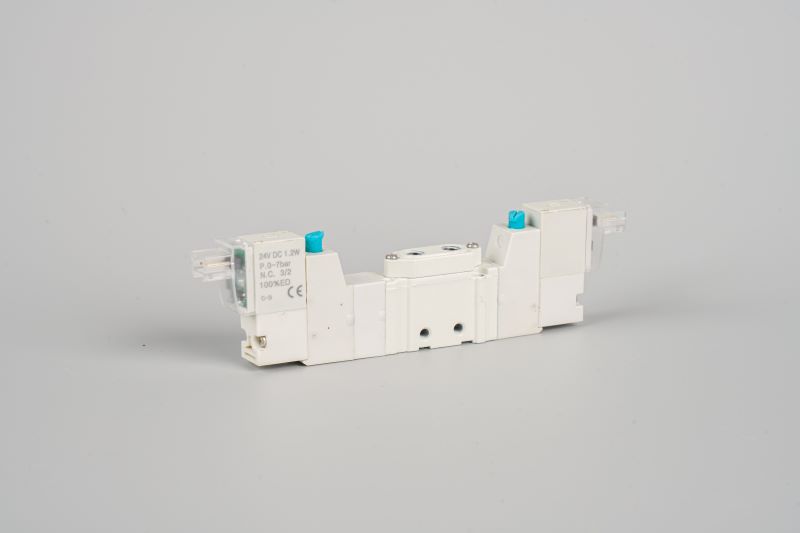

Direct-acting solenoid valve

Send Inquiry

Direct-acting solenoid valve

The direct acting solenoid valve is an automatic fluid control element that uses electromagnetic force to drive the spool action directly. The working principle is: when the coil is energized, the electromagnetic force directly pulls the valve core to change the valve opening and closing state; In case of power failure, rely on spring return. This design allows it to operate without relying on medium pressure and is particularly suitable for low pressure, vacuum or precision control scenarios.

Specification Of Direct-acting solenoid valve:

Working Pressure:

Off load 10-50/sec

Valve function:

Medium:

Air

1.5-7bar

Voltage:

DC 24V

Protection Insulation class

H

Protection Class

IP65

Power:

1.2W

Maximum Operating Frequency

Power Connector Style:

L style

Working Temp:

-10℃~+50℃

Working Life:

>30 million

Product Feature:

1-Direct-Operating Principle – direct acting solenoid valve no pilot pressure needed, ensuring reliable performance even at 0 bar (vacuum or low-pressure systems).

2- Fast & Precise – direct acting solenoid valve immediate response (10ms~50ms), ideal for high-frequency switching applications.

3-Wide Fluid Compatibility – direct acting solenoid valve works with air, water, oil, gases, and mild chemicals (material-dependent).

4-Compact & Lightweight – direct acting solenoid valve space-saving design for tight installations.

5-Energy Efficient – direct acting solenoid valve low power consumption (from 1.5W), reducing operational costs.

6- Durable Construction – direct acting solenoid valve options include brass (corrosion-resistant), stainless steel (high-pressure), and plastic (chemical-resistant) bodies.

Product Applications:

1.Medical & Laboratory – Analyzers, ventilators, fluid handling.

2. Water Treatment – Irrigation, filtration, dosing systems.

3.HVAC & Refrigeration – Coolant control, heat pumps.

4. Energy & Gas – Fuel control, compressed air systems.