Solenoid operated valve

Send Inquiry

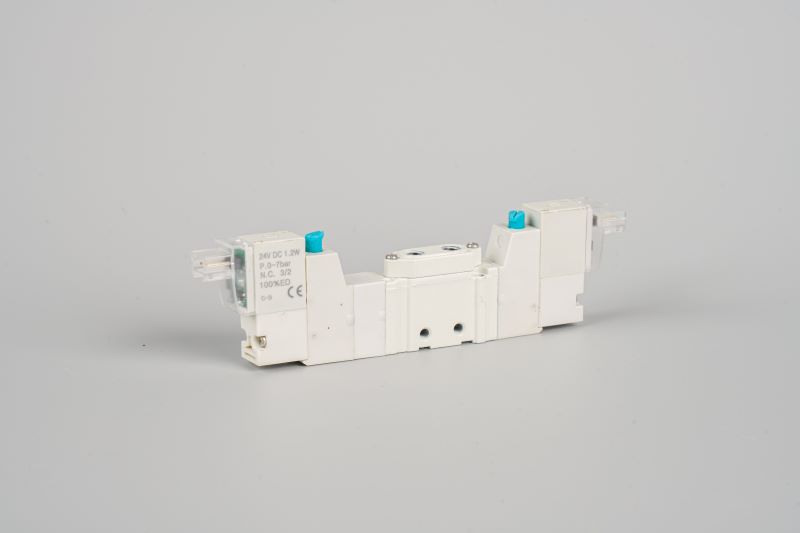

Solenoid Operated Valve

Structural composition: Solenoid Operated Valve is mainly composed of electromagnetic coils, valve core, valve seat, springs, etc. The electromagnetic coil is wound around the valve core, generating a magnetic field when energized; the valve core moves in a straight line under the action of magnetic force and spring force; the valve seat provides sealing and support for the valve core.

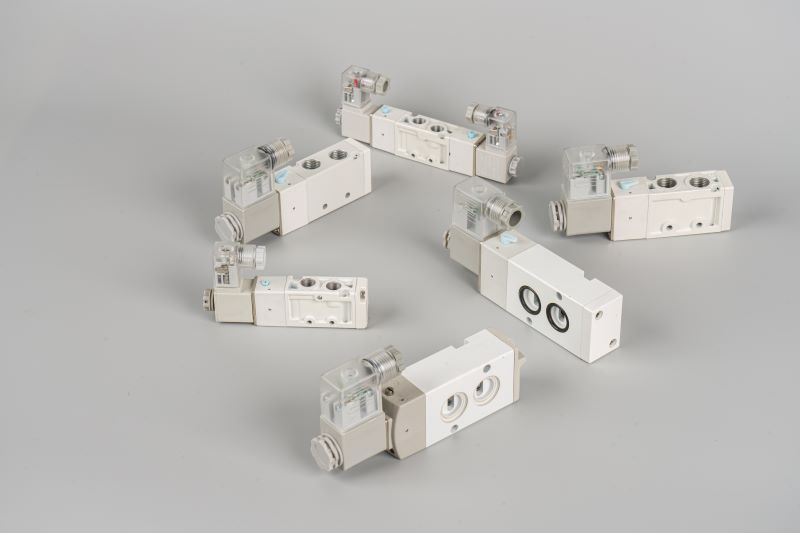

○ Diameter range: Various specifications ranging from a few millimeters to several tens of millimeters are available, such as 6mm, 10mm, 25mm, etc. The size can be selected according to the actual flow requirements.

○ Working pressure: Solenoid Operated Valve can adapt to different pressure ranges, from low pressure of a few kPa to high pressure of several MPa, such as 0.1MPa - 1.6MPa, 1.6MPa - 10MPa, etc.

○ Working temperature: Depending on different application environments, there are various models suitable for low temperatures (-40℃) to high temperatures (200℃), such as normal temperature type (-10℃ - 60℃), high temperature type (100℃ - 200℃).

○ Power supply voltage: Commonly available voltages include DC 12V, 24V, AC 110V, 220V, etc. The selection can be made according to the on-site power supply conditions.

● Material selection: The valve body materials include stainless steel, brass, and plastic. Stainless steel is corrosion-resistant and suitable for harsh environments and corrosive fluids; brass has a lower cost and good conductivity and heat conductivity; plastic is lightweight, inexpensive, and suitable for some occasions where weight and cost are sensitive.

Working Principle:

● Normally-closed solenoid valve: When not powered, the spring force keeps the valve core tightly pressed against the valve seat, causing the valve to be in a closed state and preventing the flow of fluid. When the solenoid coil is energized, the generated magnetic field overcomes the spring force and lifts the valve core, opening the valve and allowing the fluid to flow. When the power is cut off, the magnetic field disappears and the spring force returns the valve core to its original position, closing the valve.

● Normally-open solenoid valve: In contrast to the normally-closed type, when not powered, the valve is in an open state, allowing the fluid to flow freely. When energized, the electromagnetic force moves the valve core, closing the valve and cutting off the fluid passage.

Specification Of Solenoid Operated Valve:

Working Pressure:

Off load 50/sec

Valve function:

5/3

Medium:

Compressed Air

0-1.6bar

Voltage:

DC 24V

Protection Insulation class

H

Protection Class

IP65

Power:

1.2W

Maximum Operating Frequency

Power Connector Style:

L style

Working Temp:

-10℃~+80℃

Working Life:

>30 million

Product Feature:

● Quick Response: The valve core moves driven by electromagnetic force, with an extremely short response time, usually ranging from a few milliseconds to several tens of milliseconds. Solenoid Operated Valve can quickly achieve the on-off control of the fluid and meet the real-time requirements of the system.

● High Reliability: The structure is simple, with few moving parts, reducing the probability of faults. After strict quality inspection and reliability tests, Solenoid Operated Valve can maintain stable performance during long-term continuous operation.

● Precise Control: Solenoid Operated Valve can precisely control the on-off and flow of the fluid. By adjusting the current size of the electromagnetic coil or the pulse signal, it can also achieve precise regulation of the flow.

● Easy Installation and Maintenance: Solenoid Operated Valve is small in size and has multiple installation methods, allowing for direct installation on the pipeline. Maintenance is simple; only regular checks on the status of the electromagnetic coil and seals are required, and replacements can be made when necessary.

● Strong Compatibility: Solenoid Operated Valve can be integrated with various automation control systems, such as PLC (Programmable Logic Controller) and DCS (Distributed Control System), to achieve remote control and automated operation.

● Industrial Automation: In pneumatic and hydraulic systems, Solenoid Operated Valve is used to control the movement of cylinders and oil cylinders, enabling the automatic operation of mechanical equipment, such as automated production lines and robots.

● Medical Equipment: In medical instruments, Solenoid Operated Valve is used to precisely control the flow of gases and liquids, such as ventilators and blood analyzers.

● HVAC: It controls the circulation of refrigerants, hot water, and cold water to achieve temperature and humidity regulation, such as central air conditioning systems, refrigerators, and air conditioners.

● Automotive Industry: Applied in the braking systems, fuel injection systems, and exhaust emission control systems of automobiles, Solenoid Operated Valve improves the performance and safety of automobiles.

● Water Treatment: In wastewater treatment and water supply systems, Solenoid Operated Valve is used to control the on-off and flow regulation of water flow, achieving the rational utilization and treatment of water resources.