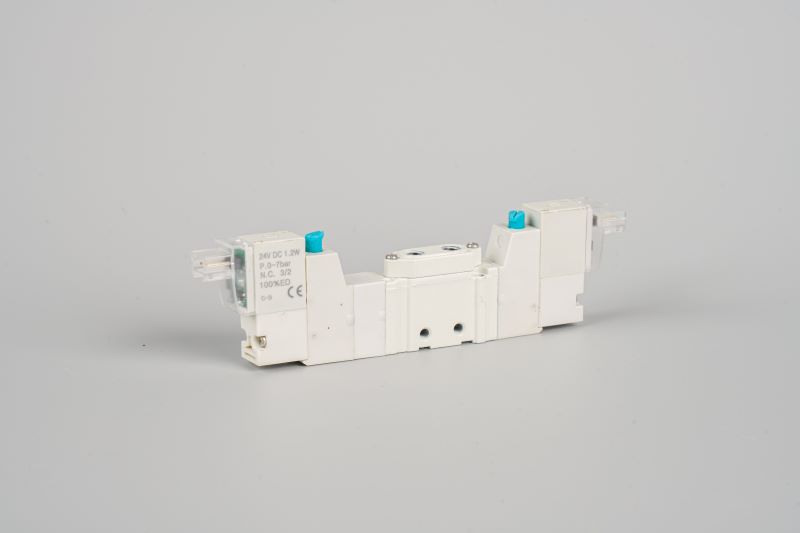

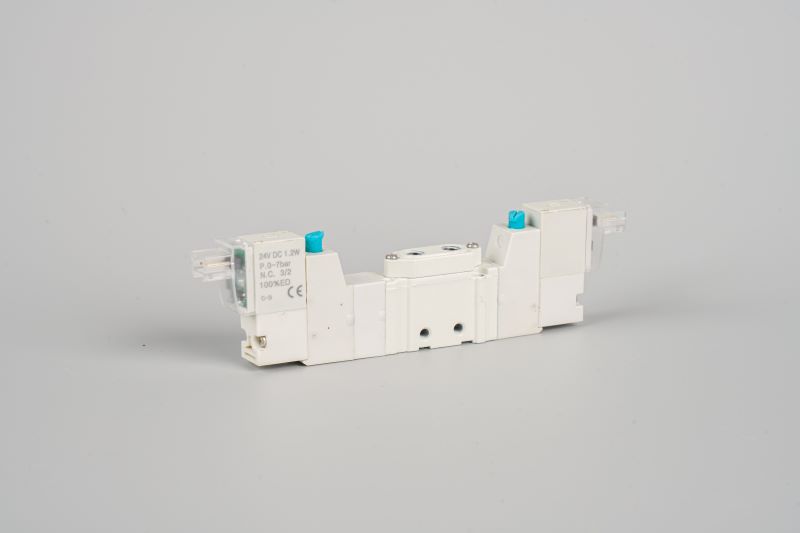

5 Ways Solenoid Valves

Send Inquiry

5 ways Solenoid Valves generally has two working positions, namely "on" and "off" states. The movement of the spool is controlled by energizing or disconnecting the electromagnetic coil, thereby changing the path of the fluid.

The common types of five-way solenoid valves are two-way five-way and three-way five-way. Two-position five-way solenoid valve can realize two different flow paths switching; The three-position five-way solenoid valve has different medium functions such as medium closure, medium exhaust and medium pressure, which can meet more complex control needs.

Specification Of

| Valve Function | 2/5 | |

| Medium Compressor | Air(To be filtered by 40um filter element) | |

| Working Type Orifice Size |

Direct action M5, 1/4, 1/8 |

|

| Flow Rate(@6bar) | >14L/min | |

| Working Pressure | 0-7bar | |

|

On/Off Response time Max.Cycling time |

<8ms >30Hz | |

| Working life | >50 Million | |

| Fixing screw | M1.7 | |

|

Duty cycle Ambient temperature |

ED 100% -5~+50℃(No freezing) |

|

| Power | 1.8W/0.5W | |

| Voltage | DC:12V, 24V/AC:110V, 220V(Others on request) | |

| Voltage range | DC:±10%/AC:-10%~+15% | |

| Degree of Protection Insulation class | Dust Proof F class | |

Advantage:

5 ways Solenoid Valves advantages include fast response speed, high control accuracy, good reliability and compact structure. It is widely used in industrial automation, pneumatic control system, hydraulic system and other fields, such as in machinery manufacturing, automobile production, chemical industry, energy field, etc., for controlling cylinder movement, valve switching, material conveying and other operations.

Different types and specifications of five-way solenoid valves may differ in terms of working pressure, flow, medium adaptability, temperature range, etc., so it is necessary to comprehensively consider the selection according to the specific application scenario and technical requirements.

Product Feature:

5. Strong flexibility: According to different control needs, choose different types (such as direct acting, pilot type, etc. ) and connection methods.

6. Good sealing: effectively prevent gas or liquid leakage, improve the efficiency and safety of the system.

7. Easy maintenance: Repair and replacement parts are relatively simple, reducing maintenance costs and downtime.

8. Wide range of application: 5 ways Solenoid Valves can be applied to a variety of media, including air, water, oil, etc.

Application:

1. 5 ways Solenoid Valves used in industrial automation production line, to control the movement of the cylinder, to achieve material handling, positioning, clamping and other operations.

2. Pneumatic tool system: 5 ways Solenoid Valves such as pneumatic wrench, pneumatic screwdriver and other tools drive control.

3. Automobile manufacturing: Participate in the assembly and delivery control of parts on the automobile production line.

4. Textile machinery: control the traction and tensioning of textile materials.