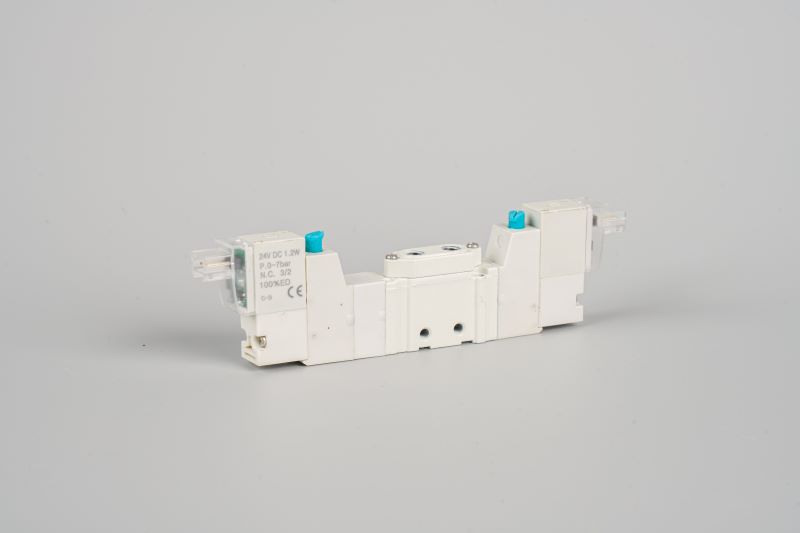

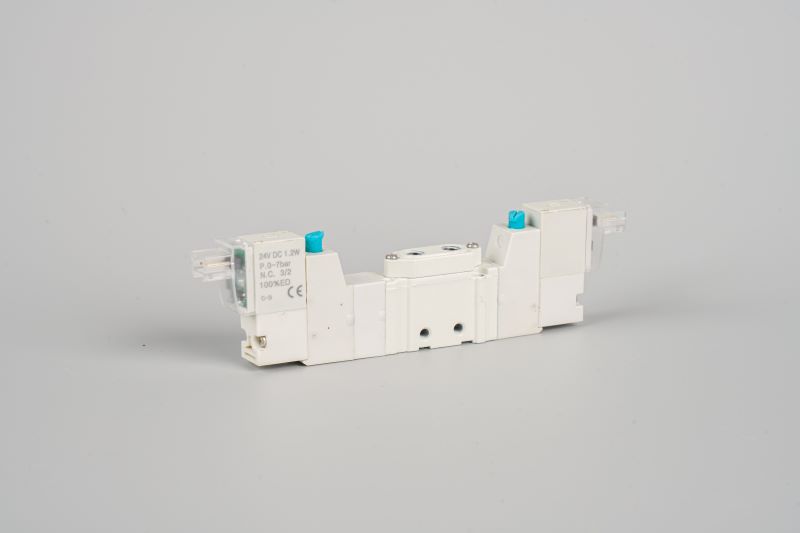

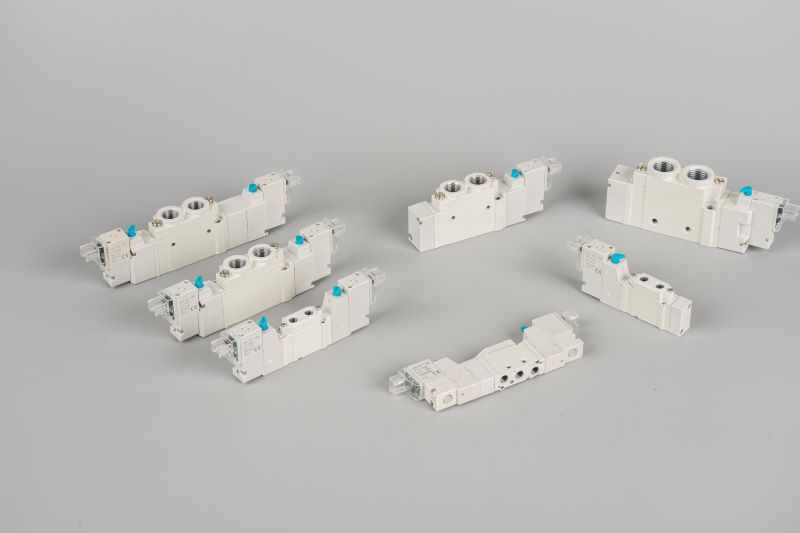

Solenoid Valve for Pneumatic Systems

Send Inquiry

Solenoid Valve for Pneumatic Systems

Solenoid Valve for Pneumatic Systems are important components for achieving automated control. They can quickly and accurately control the flow of compressed air based on the electrical signals sent by the control system, thereby driving pneumatic actuators (such as cylinders, air motors, etc.) to perform various actions, such as linear motion, rotational motion, etc.

By combining different types of electromagnetic valves and controlling them, complex pneumatic logic control can be achieved, such as sequential control, synchronous control, etc. In modern industrial production, pneumatic systems are widely used due to their advantages of cleanliness, efficiency, and safety, and the electromagnetic valve, as the control core of the pneumatic system, plays a crucial role.

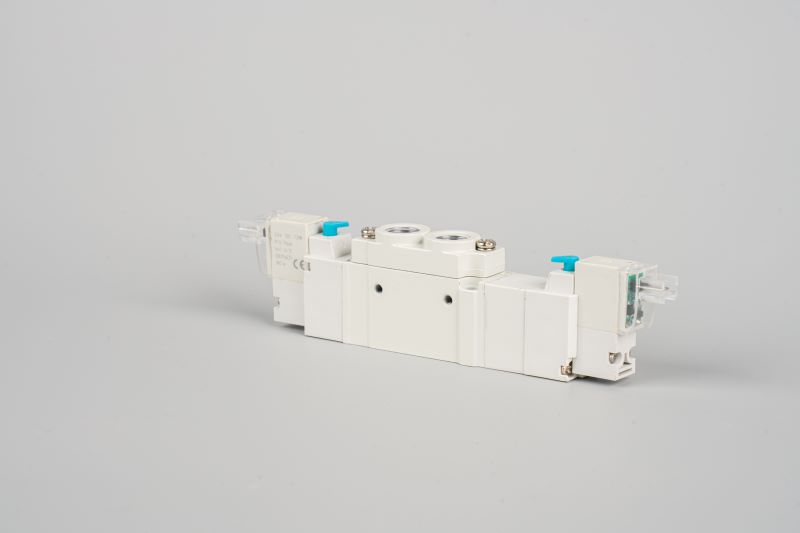

Specification Of Solenoid Valve for Pneumatic Systems:

Working Pressure:

Off load 50/sec

Valve function:

5/3

Medium:

Compressed Air

0-1.6bar

Voltage:

DC 24V

Protection Insulation class

H

Protection Class

IP65

Power:

1.2W

Maximum Operating Frequency

Power Connector Style:

L style

Working Temp:

-10℃~+80℃

Working Life:

>30 million

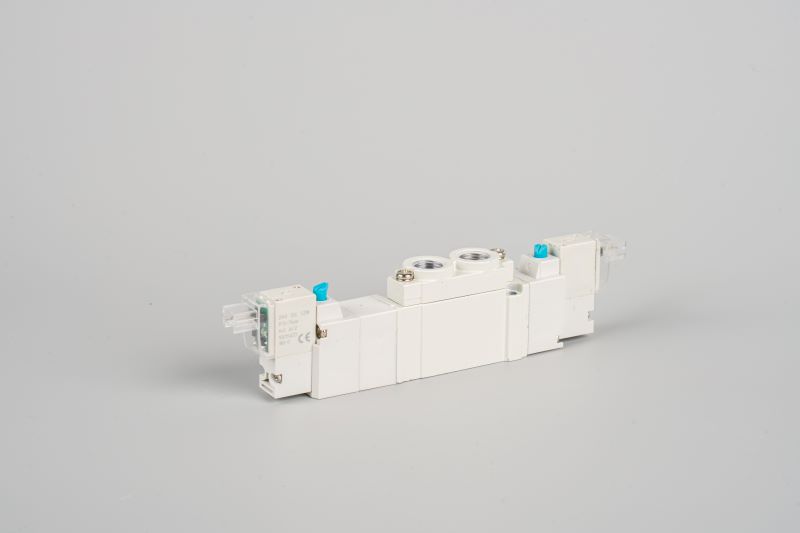

Product Feature:

● Quick response: Solenoid Valve for Pneumatic Systems can instantly achieve the on-off or direction change of the gas path, enabling the pneumatic actuating elements to move rapidly and meeting the requirements of high-speed automated production.

● Precise control: Solenoid Valve for Pneumatic Systems can precisely control the flow and direction of the gas, ensuring the accuracy and stability of the pneumatic system's operation.

● Easy integration: Compact in size and easy to install, Solenoid Valve for Pneumatic Systems can be easily integrated into various pneumatic equipment and automated production lines.

● Long lifespan: Using high-quality materials and advanced manufacturing processes, and undergoing strict quality inspections, Solenoid Valve for Pneumatic Systems has a longer service life, reducing the maintenance costs and downtime of the equipment.

● Energy-saving and environmentally friendly: When not in use, the electromagnetic coil does not consume electricity, and Solenoid Valve for Pneumatic Systems can effectively control the usage of gas, reducing energy consumption.

● Machining: Solenoid Valve for Pneumatic Systems used to control pneumatic fixtures for machine tools to achieve rapid clamping and release of workpieces; control the start and stop of pneumatic tools (such as pneumatic wrenches, pneumatic screwdrivers).

● Assembly line: In the assembly processes of electronic, automotive and other products, control the actions of pneumatic cylinders to complete operations such as part grasping, transportation and assembly.

Packaging industry

● Food packaging: Solenoid Valve for Pneumatic Systems control the opening and closing of pneumatic valves to realize packaging processes such as filling and sealing of food.

● Daily chemical packaging: Solenoid Valve for Pneumatic Systems used to control the actions of pneumatic manipulators to complete operations such as product sorting and packaging.

Automobile manufacturing

● Automobile painting: Solenoid Valve for Pneumatic Systems control the on-off of pneumatic spray guns and the flow rate of paint to ensure painting quality.

● Automobile welding: Solenoid Valve for Pneumatic Systems control the actions of pneumatic fixtures to fix welding parts, improving welding accuracy.

Robotics field

● As a control element of the pneumatic drive system of robots, enable the joints of robots to move flexibly and achieve various complex movements.