Brass Solenoid Valve

Send Inquiry

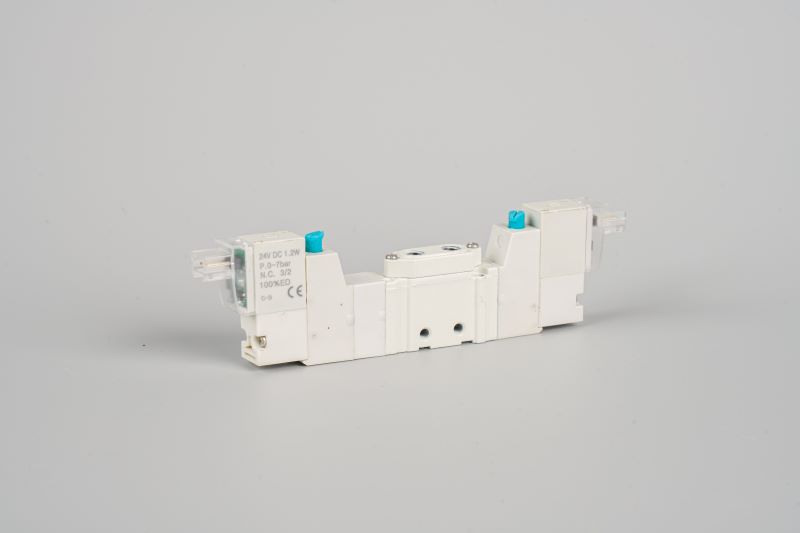

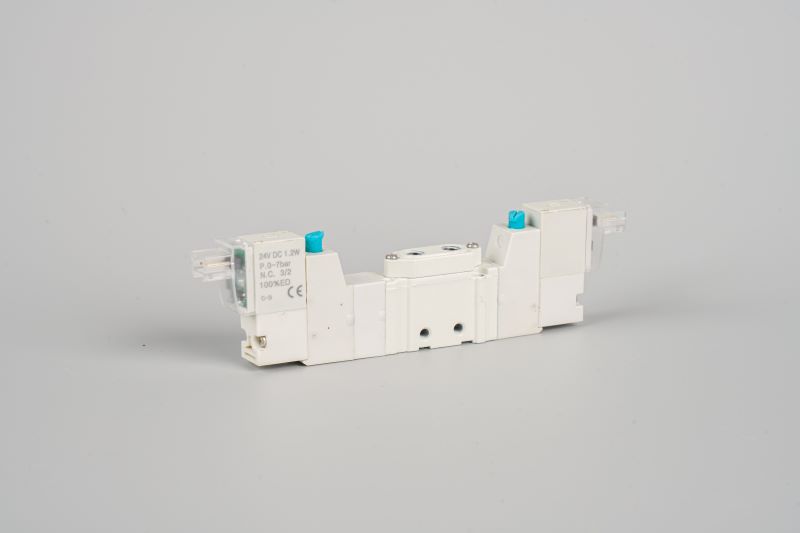

Brass Solenoid Valve Normally Closed

Basic StructureThe brass solenoid valve typically consists of the following components:Valve Body: Made of brass, which provides excellent corrosion resistance, durability, and thermal conductivity.Valve Core (Plunger): Moves within the valve to open or close the flow path.Electromagnetic Coil: Generates a magnetic field when energized, which drives the movement of the valve core.Spring: Returns the valve core to its default position when the coil is de-energized.Seals: Ensure leak-proof operation and are often made of materials like PTFE or rubber for compatibility with various fluids.

Specification Of brass solenoid valve :

Working Pressure:

Off load 50/sec

Valve function:

5/2

Medium:

Air

1.5-7bar

Voltage:

DC 24V

Protection Insulation class

H

Protection Class

IP65

Power:

1.2W

Maximum Operating Frequency

Power Connector Style:

L style

Working Temp:

-10℃~+50℃

Working Life:

>30 million

Product Feature:

1-Excellent sealing performance, effectively preventing fluid leakage.

2-Rapid response, capable of completing opening and closing actions in a short time.

3-Due to the use of brass material, it exhibits good wear and corrosion resistance, resulting in a longer service life.

Product Applications:

1-In the field of industrial automation, brass solenoid valve is used to control the flow of liquids and gases, enabling automated control of production processes.

2-In HVAC (Heating, Ventilation, and Air Conditioning) systems, brass solenoid valve regulates the flow of hot or cold water or gases.

3-In the petrochemical industry, brass solenoid valve participates in the precise control of pipeline fluids.

Future Trends:

Brass solenoid valves are evolving with advancements in technology:Smart Valves: Integration with IoT for remote monitoring and control.Energy Efficiency: Improved coil designs to reduce power consumption.High-Performance Materials: Enhanced materials for extreme temperatures and pressures.Miniaturization: Smaller valves for compact systems without compromising performance.