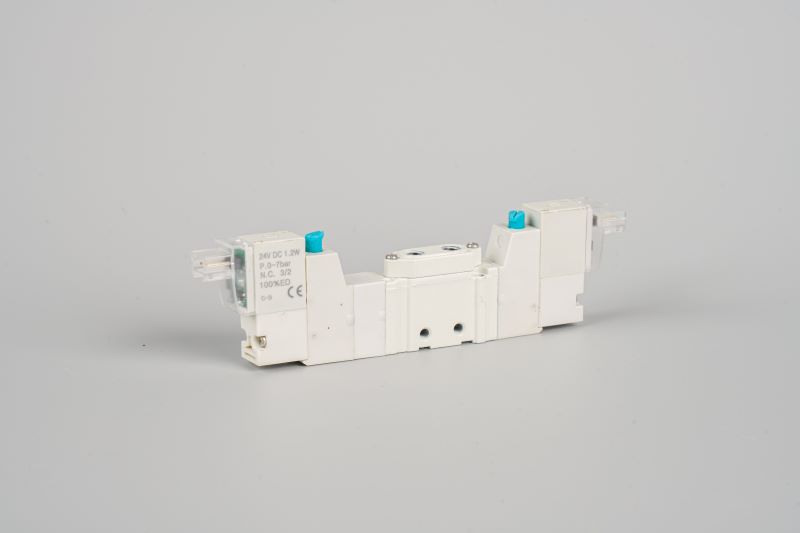

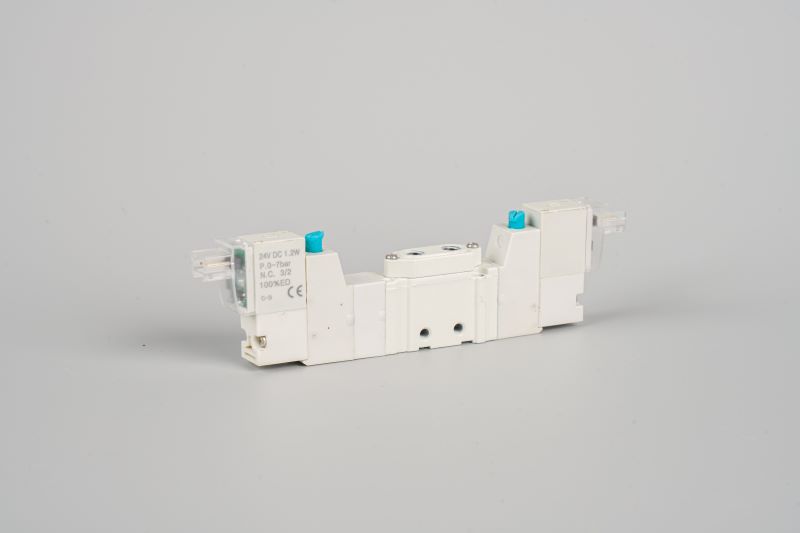

Air solenoid valves

Send Inquiry

Air solenoid valves

Air solenoid valve working principle is usually based on electromagnetic induction. When the current passes through the electromagnetic coil, a magnetic field is generated, which attracts or pushes the spool, thus opening or closing the valve channel to achieve the control of air flow.

Different types of air solenoid valves may differ in performance, structure and application scenarios, such as direct-acting, pilot-operated, etc. Users can choose according to specific needs and application conditions.

Specification Of Air solenoid valves :

Working Pressure:

Off load 50/sec

Valve function:

5/2

Medium:

Compressed Air

0-1.6bar

Voltage:

DC 24V

Protection Insulation class

H

Protection Class

IP65

Power:

1.2W

Maximum Operating Frequency

Power Connector Style:

L style

Working Temp:

-10℃~+80℃

Working Life:

>30 million

Product Feature:

1. Fast response: Air solenoid valve can be quickly opened and closed to achieve instant control of air flow.

2. Precise control: The flow and pressure of the air flow can be accurately adjusted.

3. Energy saving and high efficiency:Air solenoid valve can be closed in time when the air flow is not needed to reduce energy waste.

4. High reliability: the Air solenoid valve structure is relatively simple, the failure rate is low, and the work is stable and reliable.

5. Remote control: Remote operation can be achieved through electrical signals, which is convenient for automatic control.

1. Industrial automation: In all kinds of pneumatic systems, control the action of cylinders, pneumatic tools and other equipment.

2. Automobile manufacturing: used in automobile braking system, engine intake and exhaust control.

3. Medical equipment: such as ventilator, anesthesia machine control gas delivery.

4. Refrigeration and air conditioning system: regulate the flow of refrigerant or air to achieve the ideal temperature and humidity control.

5. Printing machinery: control inkjet, blowing and other operations.

6. Food and beverage industry: gas control for filling, packaging and other production links.

7. Environmental protection equipment: Control the flow of gas in waste gas treatment, sewage treatment and other equipment.