Why Are Solenoid Valves Transforming Fluid Control Across Industries?

2025-11-27

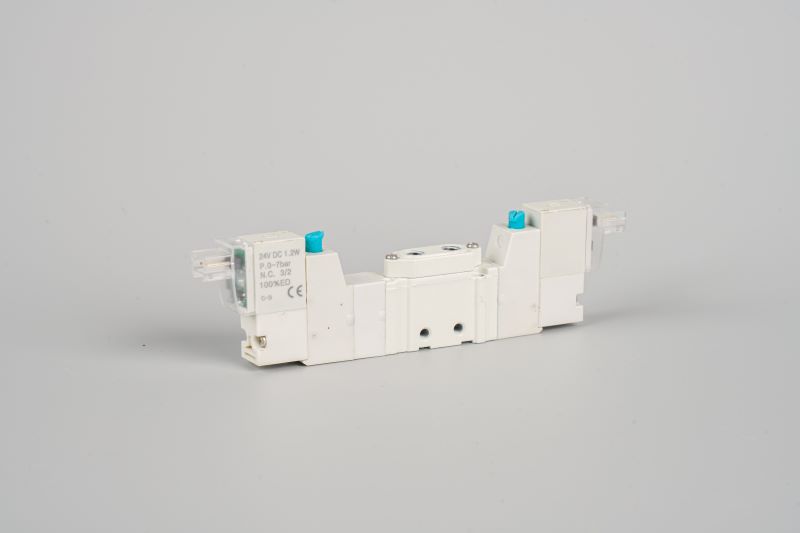

Solenoid valves are electromechanical devices engineered to control the flow of liquids or gases with precision, speed, and reliability. They operate through an electromagnetic coil that actuates the valve mechanism, enabling automated control without manual intervention. Their ability to deliver accurate on/off or proportional flow performance makes them indispensable across industries such as water treatment, HVAC, oil and gas, chemical processing, food manufacturing, automotive, and medical equipment.

This article explores what solenoid valves are, why they are widely adopted, how they function, what parameters matter most, and how industries use them to ensure efficiency, safety, and cost savings. It also examines product specifications in detail, addresses frequently asked questions, and highlights the future direction of solenoid valve technology.

Below is a professional specification overview that showcases key performance indicators and technical parameters commonly requested by engineers and procurement teams:

Solenoid Valve Key Specifications Overview

| Parameter | Description |

|---|---|

| Valve Type | 2-way / 3-way / 4-way solenoid valve options |

| Body Materials | Brass, stainless steel, plastic (PA, PVC), aluminum |

| Seal Materials | NBR, EPDM, FKM, PTFE |

| Coil Voltage Options | 12V DC / 24V DC / 110V AC / 220V AC |

| Operating Pressure Range | 0–1.6 MPa (varies by model) |

| Temperature Range | -10°C to 180°C depending on material and seal |

| Port Sizes | 1/8", 1/4", 3/8", 1/2", 3/4", 1" and custom |

| Response Time | 5–500 ms depending on configuration |

| Flow Coefficient (Cv/Kv) | Optimized for high or low flow requirements |

| Certifications | CE, RoHS, ISO-compliant manufacturing |

This set of technical parameters is widely applicable across industrial-grade solenoid valve solutions and represents the level of data engineers rely on during system design and equipment integration.

Why Do Industries Rely on Solenoid Valves and How Do They Deliver Operational Advantages?

The widespread adoption of solenoid valves stems from several performance-driven advantages. Companies increasingly depend on automated systems, and solenoid valves support this evolution through precise, consistent, and programmable flow control. Below are the core reasons why solenoid valves outperform many mechanical alternatives.

Why Solenoid Valves? Key Industry Advantages

1. High Reliability and Fast Action

Solenoid valves deliver ultra-fast response times, often within milliseconds. This makes them suitable for systems that require rapid switching, such as pneumatic automation equipment, medical devices, and high-speed production lines.

2. Energy-Efficient Control

Because the valve only consumes power during switching, solenoid valves reduce energy overhead. Low-power coils further enhance efficiency in battery-operated or remote systems.

3. Wide Material Compatibility

The ability to choose between brass, stainless steel, engineering plastics, and various sealing materials allows solenoid valves to handle water, oil, steam, corrosive chemicals, compressed air, refrigerants, and more.

4. Compact Design for Tight Installations

Even heavy-duty industrial solenoid valves tend to be compact. This enables engineers to integrate them into small equipment housings, modular systems, and mobile equipment.

5. Automation and Remote Monitoring

Solenoid valves are easily integrated into PLCs, SCADA systems, and IoT platforms, supporting automated pressure management, precise dosing, leak prevention, and environmental monitoring.

How Solenoid Valves Work: A Clear Technical Breakdown

Understanding how solenoid valves function helps engineers select the right valve type:

Step-by-Step Functioning

-

An electric current energizes the solenoid coil.

-

A magnetic field is generated inside the coil housing.

-

The magnetic field lifts or shifts a plunger or armature.

-

The plunger’s movement opens or closes the valve orifice.

-

Fluid begins or stops flowing through the valve body.

The exact behavior varies depending on whether the valve is direct-acting, pilot-operated, normally open, or normally closed.

What Are the Major Types, Applications, and Purchase Considerations for Solenoid Valves?

Solenoid valves are engineered in several functional formats designed to address unique industry needs. Understanding these distinctions allows operators to deploy the correct model for safety, reliability, lifespan, and cost optimization.

Major Solenoid Valve Types

1. Direct-Acting Solenoid Valves

Operate without pressure assistance; ideal for low-pressure or zero-pressure systems.

2. Pilot-Operated Solenoid Valves

Use system pressure to assist actuation; ideal for large flow or high-pressure systems.

3. Normally Closed (NC) Valves

Remain closed without electrical power; preferred for safety-critical systems.

4. Normally Open (NO) Valves

Stay open when not powered; suitable for cooling loops or continuous-flow systems.

5. Proportional Solenoid Valves

Allow variable flow control via modulated electrical signals; ideal for advanced automation.

Top Industrial Applications

1. Water & Wastewater Systems

Used for irrigation, filtration, dosing, and flow isolation.

2. HVAC & Refrigeration

Controls refrigerant cycles, cooling water, and air handling systems.

3. Oil & Gas Equipment

Designed to manage fuel, lubricants, hydraulic oils, and gas distribution.

4. Food & Beverage Production

Supports sanitation-compliant, non-contamination flow control.

5. Medical and Laboratory Devices

Used for precise dosing, gas switching, pressure management, and sterilization equipment.

How to Select the Right Solenoid Valve? Key Considerations

Professionals typically evaluate:

-

Operating pressure and differential pressure

-

Fluid type, viscosity, and temperature

-

Port size and connection thread

-

Body and seal material compatibility

-

Voltage compatibility

-

Desired switching speed

-

Environmental protection (IP rating)

-

Certification requirements (CE, RoHS, etc.)

Engineers often rank material compatibility and pressure requirements as the leading factors because incorrect selection can lead to failure, leakage, and equipment damage.

Frequently Asked Questions (Two Common Questions)

Q1: How long do solenoid valves usually last in industrial applications?

A1: The lifespan depends on fluid quality, coil voltage stability, operating pressure, and cycle frequency. High-grade solenoid valves used in clean systems can last hundreds of thousands to millions of cycles. Valves equipped with stainless-steel bodies and PTFE seals typically perform best in corrosive or high-temperature environments. Regular cleaning and voltage stabilization significantly extend the service life.

Q2: Can solenoid valves operate continuously without overheating?

A2: Yes, but this depends on coil design, duty cycle rating, ambient temperature, and cooling conditions. Continuous-duty coils are engineered for long-term energization, while intermittent-duty coils must not remain powered for extended periods. Systems with high ambient heat or restricted airflow should use coils with heat-dissipating housings or incorporate additional cooling strategies.

How Are Solenoid Valves Evolving and Why Will Future Technologies Matter?

As industrial automation accelerates, solenoid valves are entering a phase of rapid innovation. Manufacturers increasingly integrate advanced materials, smart monitoring, and improved energy efficiency, aligning with global trends in intelligent manufacturing and sustainability.

Key Future Trends in Solenoid Valve Development

1. Smart Sensor Integration

Valves with built-in sensors can transmit real-time data such as temperature, pressure, vibration, and flow. This supports predictive maintenance strategies and reduces downtime.

2. Miniaturization and Micro Solenoid Valves

As medical and semiconductor equipment shrinks in size, micro-valves requiring extremely low power consumption and high precision are in high demand.

3. Eco-Friendly, Low-Power Coil Designs

Reduced energy consumption is a major priority across industries. Future valves will increasingly use ultra-low-power coils while maintaining fast response times.

4. Advanced Material Engineering

More corrosion-resistant alloys, enhanced polymer composites, and improved sealing materials will increase durability in extreme chemical and temperature environments.

5. Improved Safety and Compliance

Stricter industry standards—especially in food, pharmaceutical, and high-pressure systems—will drive the adoption of valves with enhanced certification and safety testing.

Why High-Quality Solenoid Valves Matter and How Qimao Supports Industrial Needs

Solenoid valves play a critical role in controlling fluid and gas flow with precision, reliability, and speed. They offer essential advantages such as efficient automation, durable construction, and compatibility with a wide range of industrial media. As industries adopt smarter and more energy-efficient systems, solenoid valves will continue evolving toward higher performance and intelligent connectivity.

For companies seeking dependable, professionally engineered solenoid valves, Qimao provides solutions built on rigorous quality control, advanced manufacturing standards, and industry-focused engineering. Whether the requirement involves water management, chemical processing, pneumatic systems, or specialized automation, Qimao’s solenoid valve portfolio supports long-term reliability and performance.

For custom specifications, engineering assistance, or product sourcing, contact us to obtain tailored solutions that meet the exact requirements of your application.