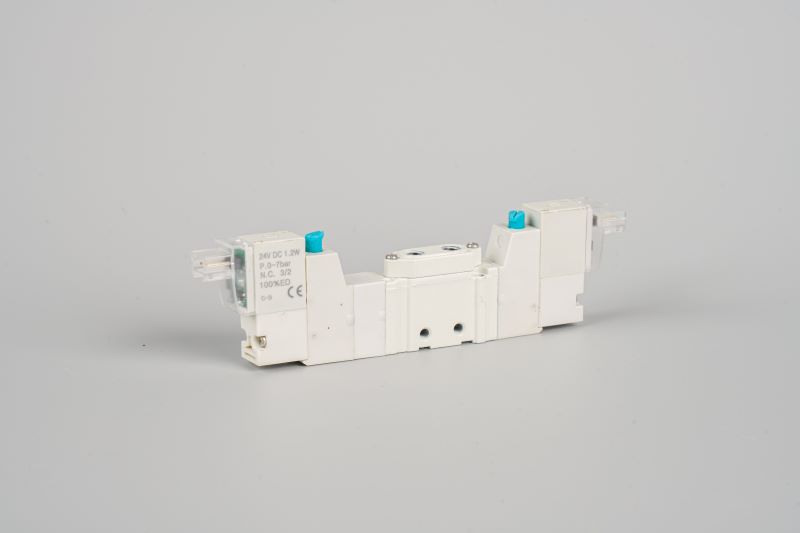

FRL air filter

Send Inquiry

Pneumatic components FRL air filter is a combination device that plays a key role in pneumatic systems.

FRL consists of Filter, Regulator and Lubricator.

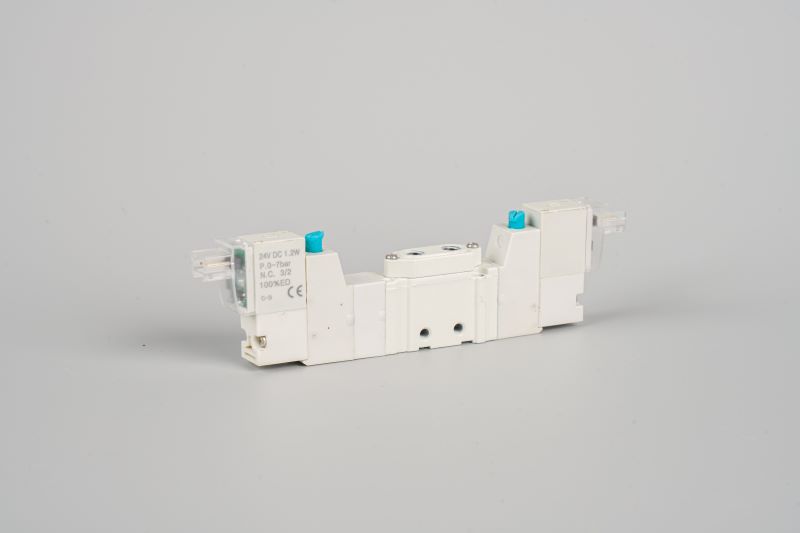

Specification Of:

| Model: | Port Size: |

| AW1000-M5 | M5 |

| AW2000-01 | 1/8 |

|

AW2000-02 |

1/4 |

|

AW3000-02 |

1/4 |

|

AW3000-033/8 |

3/8 |

|

AW4000-03 |

3/8 |

|

AW4000-04 |

1/2 |

|

AW4000-06 |

3/4 |

|

AW5000-063/4 |

3/4 |

|

AW5000-10 |

1 |

Detail:

Pneumatic components FRL air filter are indispensable and crucial parts of pneumatic systems. FRL air filter consists of three parts: a filter, a pressure regulator, and an oil mist lubricator. The filter can effectively remove dust, impurities, moisture, and oil droplets from compressed air, preventing these contaminants from causing wear, blockage, and corrosion to subsequent pneumatic components, thus ensuring the normal operation of the pneumatic system. The pressure regulator can adjust the input high-pressure gas to a stable output pressure as required by different pneumatic equipment, ensuring that the equipment operates under appropriate pressure and improving the stability and control accuracy of the system. The oil mist lubricator adds an appropriate amount of lubricating oil mist to the compressed air that has been filtered and pressure-regulated, lubricating the pneumatic components, reducing friction and wear, extending the service life of the components, and lowering maintenance costs. In summary, the FRL air filter combination ensures that compressed air is effectively treated and regulated before entering the pneumatic system, providing an important guarantee for the efficient, stable, and reliable operation of the pneumatic system.

Product Feather:

1. Filtration function: FRL air filter can effectively remove impurities, moisture and oil mist in compressed air, prevent damage to pneumatic components, and extend their service life.

2. Pressure adjustment: The output gas pressure can be accurately adjusted according to the actual demand, to ensure that the pneumatic equipment works under the right pressure, improve the stability and accuracy of the work.

3. Lubrication: Add an appropriate amount of lubricating oil to the compressed air to lubricate the pneumatic components and reduce wear and friction.

4. Compact design: compact structure, easy installation, space saving.

5. High reliability: The use of high-quality materials and advanced manufacturing processes, with good durability and stability, can operate reliably in harsh working environments for a long time.

Product Application:

1. Industrial automation production line: FRL air filter used to control the action of various executive components, such as cylinders, air motors, etc.

2. Machine tool equipment: Provide a stable air source and appropriate lubrication for the pneumatic parts of the machine tool.

3. Packaging machinery: FRL air filter ensure the normal operation of the pneumatic device during the packaging process.

4. Automotive manufacturing: plays a role in pneumatic tools and equipment on automotive production lines.