How Do Directional Valves Control the Flow of Power in Hydraulic and Pneumatic Systems?

2025-10-23

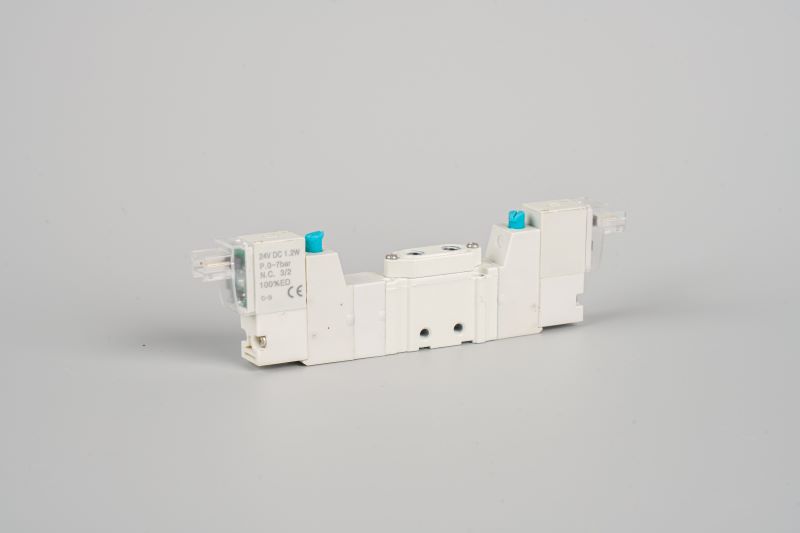

Directional valves are the unsung heroes behind the seamless performance of modern hydraulic and pneumatic systems. They direct and regulate the flow of pressurized fluid or air, ensuring that machinery operates efficiently, safely, and precisely. This article explores what directional valves are, how they function, why they're crucial for industrial automation, and what sets Ningbo Qimao Pneumatic Co., Ltd. apart as a trusted manufacturer in this field. Readers will also find detailed product specifications, performance parameters, and a practical FAQ section that addresses the most common questions from users and engineers.

Table of Contents

-

What Are Directional Valves and How Do They Work?

-

Why Are Directional Valves So Critical in Pneumatic and Hydraulic Applications?

-

How Ningbo Qimao Pneumatic Co., Ltd. Delivers Reliability and Innovation

-

FAQ: Common Questions About Directional Valves

-

Conclusion and Contact Information

What Are Directional Valves and How Do They Work?

Directional valves are mechanical or electro-mechanical devices designed to control the direction of fluid flow in hydraulic or pneumatic systems. By opening, closing, or changing the passage of flow, these valves determine the movement direction of actuators, such as cylinders or motors.

In essence, Directional Valves decide whether energy will move a piston forward or backward, start or stop a process, or hold a load in position. Without them, systems would lack control and precision.

There are several types of directional valves, including:

-

2/2-way valves (two ports, two positions): Simple start/stop flow control.

-

3/2-way valves: Common in pneumatic systems for controlling single-acting cylinders.

-

4/2-way or 4/3-way valves: Typical in hydraulic applications, enabling bidirectional motion of double-acting cylinders.

-

Solenoid-operated directional valves: Electrically actuated, allowing integration with PLC systems and automation control.

Each valve type is defined by the number of ports and flow paths it offers, giving engineers flexibility to design efficient and customized circuits.

Why Are Directional Valves So Critical in Pneumatic and Hydraulic Applications?

Directional valves are essential components that make automation and heavy machinery responsive, safe, and reliable. Their importance lies in the following functions:

-

Flow Control: Precisely directs compressed air or hydraulic fluid to actuators.

-

Pressure Regulation: Maintains system pressure within safe operating limits.

-

Operational Safety: Prevents reverse flow and unintentional movements.

-

Energy Efficiency: Reduces waste of compressed air or hydraulic oil.

-

Automation Compatibility: Enables synchronized operation in robotics and production lines.

In industries like automotive manufacturing, construction equipment, packaging, and robotics, Directional Valves are integral to achieving fast response times, repeatable precision, and low maintenance costs.

Product Specifications and Technical Data

The following table provides key performance parameters for Directional Valves designed and manufactured by Ningbo Qimao Pneumatic Co., Ltd.

| Parameter | Specification | Description |

|---|---|---|

| Working Medium | Compressed Air / Hydraulic Oil | Filtered and lubricated air for pneumatics; mineral oil for hydraulics |

| Pressure Range | 0.15 – 1.0 MPa | Suitable for standard industrial environments |

| Operating Temperature | -5°C to +60°C | Designed for reliable operation under varying conditions |

| Port Size | G1/8", G1/4", G3/8", G1/2" | Available in multiple thread standards |

| Flow Rate | Up to 1600 L/min | Ensures stable flow for medium to large systems |

| Valve Type | 2/2, 3/2, 4/2, 4/3 | Available in manual, mechanical, and solenoid actuation |

| Voltage Options | 12V DC, 24V DC, 110V AC, 220V AC | Compatible with most industrial control systems |

| Material | Aluminum Alloy, Brass, Stainless Steel | Corrosion-resistant and long-lasting |

| Mounting Style | Sub-base, Manifold, or Inline | Easy installation and maintenance |

| Service Life | > 10 million cycles | Engineered for endurance and reliability |

Performance Benefits

-

High response sensitivity and low leakage design

-

Modular construction allows easy maintenance and replacement

-

Strong resistance to wear and corrosion

-

Energy-saving due to low internal friction

-

Compact and lightweight design suitable for space-limited applications

Additional Configurations Available

| Model Series | Control Type | Port Size | Application Field |

|---|---|---|---|

| QM-2V Series | Manual Lever | G1/4" | Light machinery, packaging equipment |

| QM-3V Series | Pneumatic Pilot | G3/8" | Air cylinders, conveyor systems |

| QM-4V Series | Solenoid Control | G1/2" | Automation lines, robotics |

| QM-4V500 Series | Double Solenoid | G3/4" | Hydraulic systems, press machines |

Each series undergoes strict performance testing to ensure it meets ISO and CE certification standards, reinforcing its durability and reliability.

How Ningbo Qimao Pneumatic Co., Ltd. Delivers Reliability and Innovation

Ningbo Qimao Pneumatic Co., Ltd. is a professional manufacturer specializing in pneumatic components, including Directional Valves, air cylinders, fittings, and other automation parts. With years of engineering expertise and advanced production technology, the company has established itself as a trusted partner in global automation supply chains.

QIMAO Pneumatic has delivered reliability with a deep researching of customer requirment. We are China manufacturer of Solenoid Valves, Cylinder, Armature core, F.R.L , Coil etc for pneumatic professional and industrial applications. Our aim to provide customers with high performance products and high quality professional services. Our products are engineered for performance and lasting customer value.

Company Advantages:

-

Precision Manufacturing: All valves are CNC machined with tight tolerances to ensure stability and accuracy.

-

Strict Quality Control: Each valve is tested for leakage, pressure endurance, and electrical reliability.

-

Customization Service: Tailor-made solutions available based on client specifications.

-

Global Reach: Exported to over 60 countries with a strong reputation for quality and service.

-

Fast Delivery & Technical Support: Reliable logistics and prompt after-sales service.

The company's focus on energy-efficient, durable, and user-friendly valve solutions allows it to serve industries such as automotive, food processing, textile machinery, and automation lines with exceptional performance.

FAQ: Common Questions About Directional Valves

Q1: What is a directional valve used for?

A: A directional valve controls the path of fluid or air in a hydraulic or pneumatic circuit, directing motion to different actuators.

Q2: How do I select the right directional valve for my application?

A: Consider your system pressure, flow rate, control method (manual, pneumatic, or solenoid), and port size.

Q3: Can a directional valve control both air and oil?

A: Some models are designed for both media, but it's important to choose one rated for your specific fluid type and viscosity.

Q4: What causes a directional valve to malfunction?

A: Common causes include contamination, worn seals, or incorrect voltage supply for solenoid-operated models.

Q5: How often should directional valves be maintained?

A: Regular inspection every 6–12 months is recommended to ensure optimal performance and safety.

Q6: Are directional valves compatible with all pneumatic fittings?

A: They are compatible with most international standard fittings such as G, NPT, and BSP threads.

Q7: What's the difference between 3/2-way and 4/3-way valves?

A: A 3/2-way valve controls single-acting cylinders, while a 4/3-way valve manages double-acting actuators with more control positions.

Q8: Can I use directional valves in automated systems?

A: Yes, solenoid-operated types integrate easily with PLCs and automation controllers.

Q9: How do directional valves improve energy efficiency?

A: They minimize pressure loss and prevent unnecessary air or oil consumption through precise control.

Q10: Where can I buy reliable directional valves?

A: You can purchase directly from Ningbo Qimao Pneumatic Co., Ltd., a leading manufacturer known for quality and innovation.

Conclusion and Contact Information

In conclusion, Directional Valves play a vital role in ensuring accurate flow control and system efficiency in both pneumatic and hydraulic environments. They enable industries to achieve automation, safety, and reliability — essential factors for today's competitive market.

With precision engineering, superior materials, and decades of experience, Ningbo Qimao Pneumatic Co., Ltd. stands out as a trusted source for high-performance valve solutions. Whether you need standard models or customized configurations, the company provides complete technical support and fast delivery worldwide.

Contact Us:

For inquiries, technical consultations, or customized orders, please contact Ningbo Qimao Pneumatic Co., Ltd. through our official website or email. Our professional team is ready to help you find the most efficient Directional Valves for your application.