How Does a Digital Pressure Switch Improve System Efficiency

When it comes to industrial automation and fluid control, precision matters. Even a slight variation in pressure can lead to system inefficiencies, increased energy consumption, or even equipment failure. That’s where a Digital Pressure Switch comes into play. But how exactly does it enhance system performance? Let’s break it down.

What Makes a Digital Pressure Switch More Efficient Than Traditional Models?

Unlike mechanical pressure switches that rely on physical springs and diaphragms, a Digital Pressure Switch uses advanced sensors and microprocessors to deliver unmatched accuracy. Here’s why it’s a game-changer:

-

Higher Precision – Eliminates mechanical hysteresis for consistent readings.

-

Adjustable Setpoints – Fine-tune pressure thresholds on the fly without manual recalibration.

-

Real-Time Monitoring – Provides instant feedback to prevent system overloads.

-

Lower Energy Consumption – Optimizes pump and compressor cycles, reducing wasted power.

At QM, we’ve engineered our Digital Pressure Switch to meet the toughest industrial demands while keeping efficiency at the forefront.

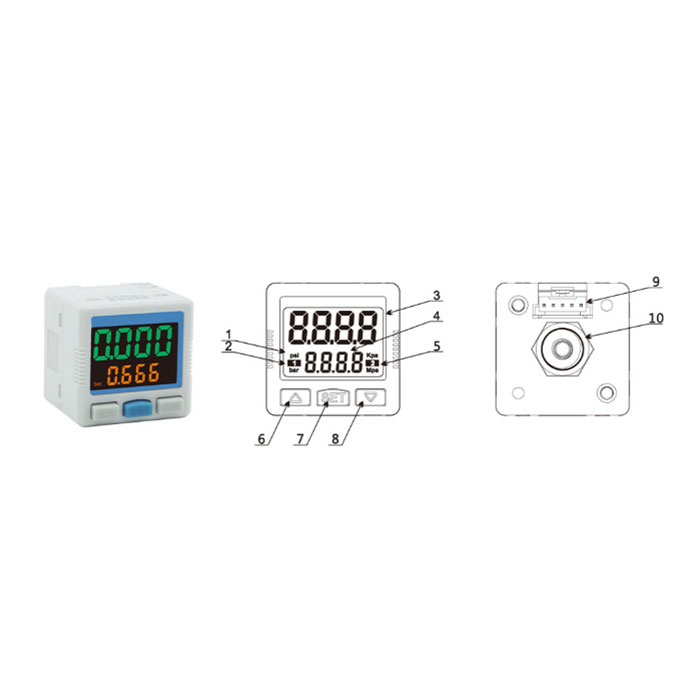

How Do Key Features of a QM Digital Pressure Switch Enhance Performance?

Our QM Digital Pressure Switch is packed with intelligent features designed to maximize uptime and minimize downtime. Here’s a quick breakdown of its core specifications:

Key Parameters of QM Digital Pressure Switch

| Feature | Specification | Benefit |

|---|---|---|

| Pressure Range | 0-1000 PSI (customizable) | Adapts to various industrial applications |

| Accuracy | ±0.5% Full Scale | Ensures reliable and repeatable performance |

| Output Signal | 4-20mA, 0-10V, RS485 Modbus | Seamless PLC & SCADA integration |

| Response Time | <10ms | Prevents pressure spikes and system damage |

| IP Rating | IP65 (Dust & Water Resistant) | Suitable for harsh environments |

| Display | OLED with backlight | Easy reading in low-light conditions |

With these specs, our Digital Pressure Switch doesn’t just measure pressure—it actively improves system reliability and energy efficiency.

What Are the Real-World Benefits of Switching to a Digital Pressure Switch?

Many industries still rely on outdated mechanical switches, unaware of the hidden costs they bring. Here’s how upgrading to a QM Digital Pressure Switch solves common pain points:

-

Reduces Maintenance Costs – No moving parts mean less wear and tear.

-

Prevents False Tripping – Eliminates mechanical drift for stable operation.

-

Extends Equipment Lifespan – Smart pressure management reduces strain on pumps and compressors.

-

Enables Predictive Maintenance – Real-time diagnostics alert you before failures occur.

One of our clients in the HVAC sector reported a 15% drop in energy bills after switching to our Digital Pressure Switch, proving that smarter technology pays off.

How Can You Integrate a QM Digital Pressure Switch Into Your System?

Installation is straightforward, but optimizing settings ensures peak performance. Here’s what we recommend:

-

Mount the sensor in a vibration-free location for accurate readings.

-

Set pressure thresholds via the intuitive interface (no external tools needed).

-

Connect to your control system using the preferred output (analog or digital).

-

Monitor and adjust as needed via the OLED display.

Our team at QM provides full technical support to ensure seamless integration—because your efficiency is our priority.

Ready to Boost Your System’s Efficiency? Contact QM Today!

If you’re tired of dealing with unreliable pressure controls and wasted energy, it’s time to upgrade. The QM Digital Pressure Switch delivers precision, durability, and smart automation—all in one robust package.

Contact us now to discuss your application, request a demo, or get a customized solution tailored to your needs. Let’s make your system smarter, together.